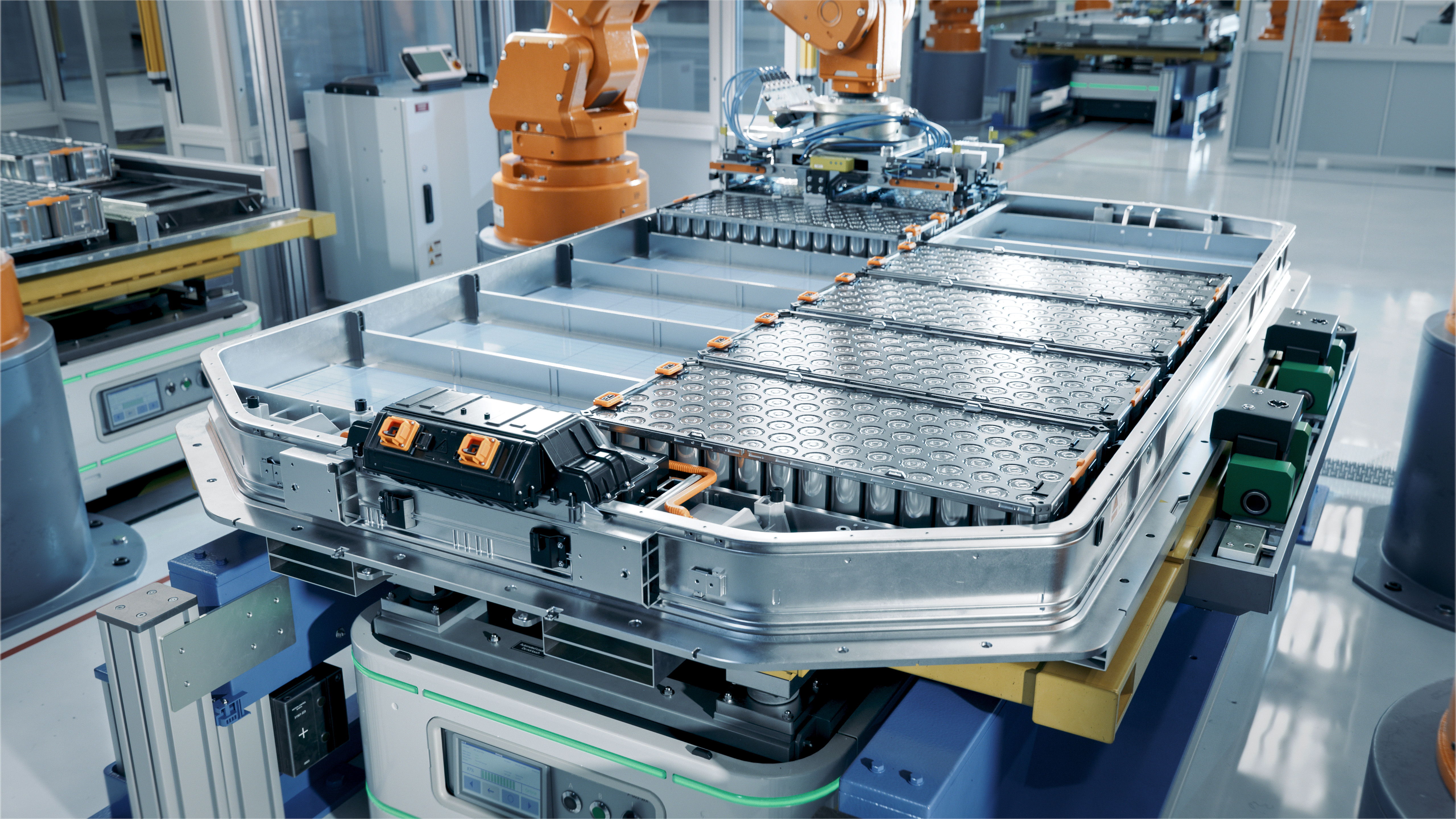

Zircotec to lead vital ceramic coating research to enable lightweight material use in Electric Vehicle (EV) battery enclosures and cooling plates

September 17, 2024

- Company secures significant government funding through the Advanced Propulsion Centre UK (APC) for market-ready ceramic coating solutions that meet the new demands of Electric Vehicles

- Proprietary coatings integrating dielectric, flameproofing and thermal properties for improved performance

- ‘CeraBEV’ project will allow OEMs to replace heavy-duty steel with lightweight aluminium and plastic composite materials in EV battery enclosures, and secure improved efficiency for battery cooling plates

- Pioneering research will support drive to optimise weight and extend range of EVs

- The project will accelerate UK’s battery energy storage technology capabilities

17 September 2024 - Abingdon: Zircotec, the thermal technologists that have owned the science of heat management for more than 30 years, have secured government funding through the Advanced Propulsion Centre UK (APC) to develop a single proprietary ceramic coating that will unlock the use of lightweight materials – including aluminium and plastic composites – across EV battery enclosures and cooling plates.

The Government-supported ‘CeraBEV’ (Ceramics for BEVs) project, which forms part of the government’s work to ensure the UK remains at the cutting-edge of battery technology, will last for 12 months. Zircotec has been installed as the lead partner, while Cranfield University is the project partner responsible for coating testing and evaluation.

In almost all cases, battery enclosures on today’s EVs are manufactured from heavy-duty steel. In a bid to reduce the weight of EVs and improve their range, alternative and lightweight materials are needed. Examples include aluminium and plastic composites. Alongside this, the efficiency of aluminium cooling plates within the battery pack is hampered by the required electrical insulation coupled with its typically low level of thermal conductivity. Significant improvements in cooling plate efficiency can be achieved through thin, high-performance electrical insulation with enhanced thermal conductivity.

Dominic Graham, Zircotec Engineering Director, said: “The key to unlocking the use of new, lightweight materials across battery enclosures and cooling plates in EVs is being able to develop and effectively apply high-performance coatings that ensure the safe thermal and electrical operation of the substrate.

“The Advanced Propulsion Centre ‘CeraBEV advanced route to market demonstrator’ project allows our engineers to develop world-first, all-in-one dielectric and flameproof ceramic coatings that will address and overcome the significant thermal management and electrical insulation challenges associated with the lightweight materials OEMs want to use on their vehicles.

Andrew Donachie, Zircotec COO, said: “We’re delighted to be selected to receive this APC funding which will not only enable Zircotec to extend its current ceramic coating expertise within the EV sector, but will also accelerate the UK’s battery energy storage technology capability through ceramic coating research that has the power to transform material use in the battery electric vehicle sector.”

Ian Constance, APC CEO, said: “The Advanced Route to Market Demonstrator delivers cutting-edge technology in a short period of time. With the investment from both industry and government, the projects will not only demonstrate the strength and breadth of the zero-emission automotive sector in the UK, but hopefully the acceleration of these to commercialisation. We will certainly see concepts that will go into real-world every-day vehicles, helping the UK achieve its net zero goals.”

To deliver its research, Zircotec will develop its current ElectroHold® coatings range to provide high-performance dielectric, flameproofing and EMC shielding properties.

These existing products are lightweight, can be easily packaged into existing automotive design infrastructures, protect against water ingress, corrosion and chemical attack, and provide the highest performance and adherence levels during normal operating conditions. They have also been proven at the top level of electric motorsport.

The specific features of each product are:

ElectroHold DIELECTRIC

Available as a lightweight polymer-based coating or a ceramic coating with a polymer sealant. Prevents electrical conductivity between components to ensure safety and eliminate the risk of short-circuiting and overheating of batteries and cells. Coatings provide high dielectric strength on various components, offering up to 42 kV/mm or 10 kV/mm coupled with good thermal conductivity to aid heat removal.

ElectroHold FLAMEPROOF

A proven, lightweight, high-performance thermal barrier coating for battery enclosures and covers that gives short-term flame protection at 1,400°C and extended protection at 700°C. Suitable for use on steel, aluminium, composite and plastic substrates without any post-application electrical impact.

ElectroHold EMC SHIELD

An electrically-conductive battery enclosure and cover coating that prevents EM leakage and protects critical components from EM interference. This high-integrity, metallic-based coating is ultra-thin (~50 μm), lightweight (~135 g/m2), and can operate at temperatures up to 600ºC.

Dominic Graham added: “Our skills and experience in developing thermal management solutions for OEMs and top-flight motorsport, including F1, are well known. But the Electric Vehicle market is an area we’ve been focusing on heavily during the last 12 months by developing out our current thermal science to create a new breed of ElectroHold® solutions. This proven technology will provide the platform for our work towards delivering the CeraBEV project.”

To discover more:

www.zircotec.com/solutions/ev-solutions

ENDS

Editors’ notes

Zircotec is a UK company that has owned the science of thermal management for the last three decades. It is a trusted supplier of heat management expertise and ultra-high performance products to customers located across the world.

Based in Abingdon, Oxfordshire, Zircotec’s origins can be traced back to the Atomic Energy Authority where first-generation plasma-sprayed coatings were developed for use in the nuclear industry. Today, the company’s ceramic coating and heat shielding solutions are the number one choice for customers in various sectors including automotive, motorsport and industry.